- Overview

- application area

- technical data

- Equipment

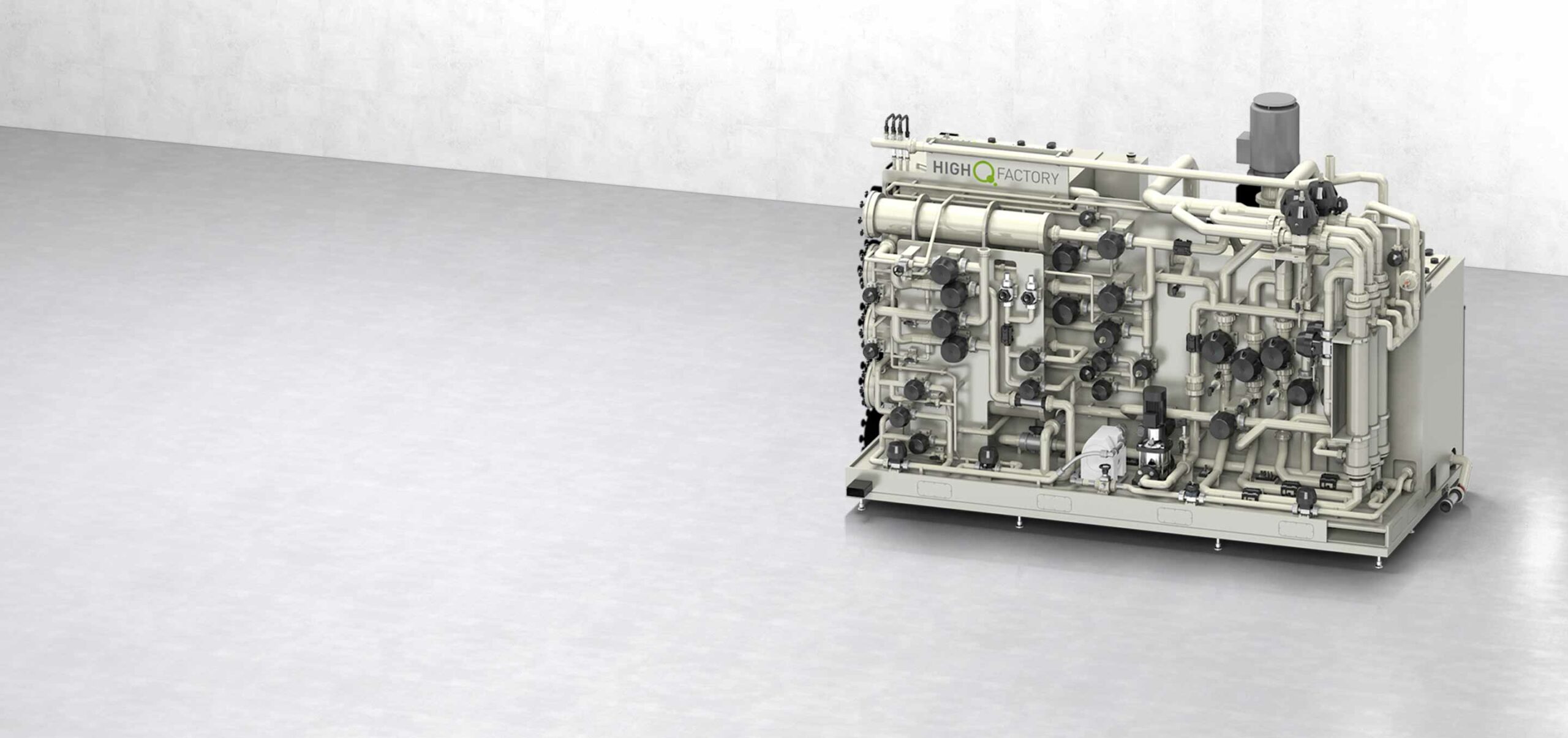

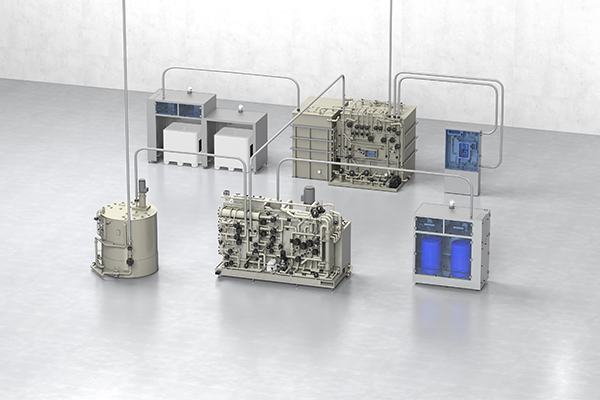

The Recycling Module 3UF

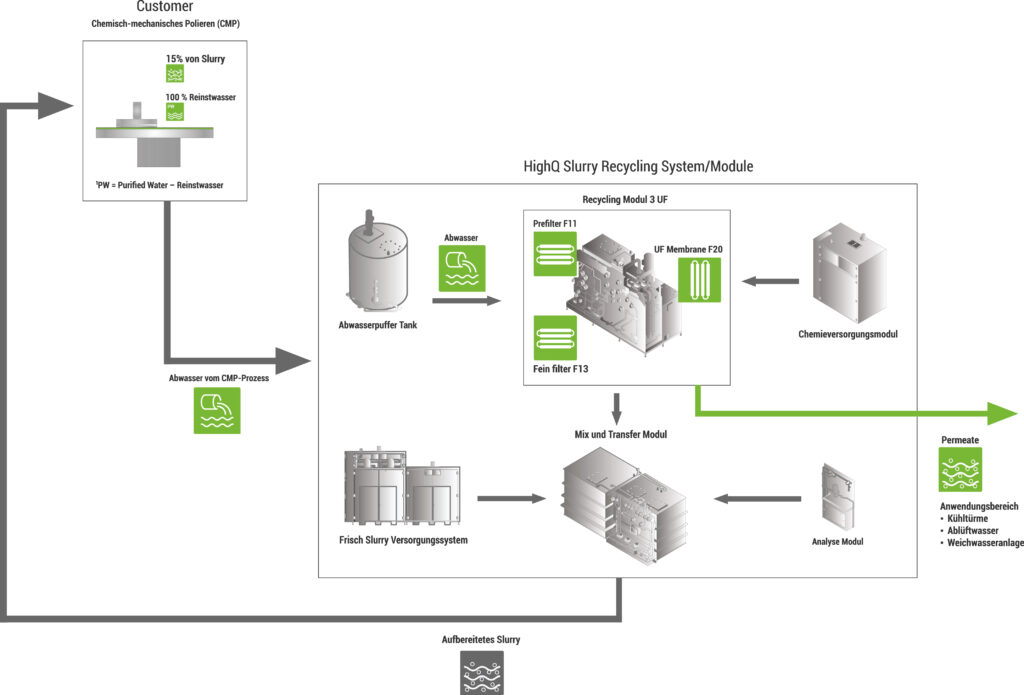

Wastewater from the CMP process is to be recycled on site, being fed into the integrated recirculation tank via the pre-filtration stages. In further process steps, the wastewater is concentrated in the recirculation process via the 3 ultrafiltration modules and simultaneously to permeate (water) is extracted from the process. Due to the patented backflush process, the lifetime of these cost-intensive UF modules will be significantly increased. After ultrafiltration, the concentrated slurry is made available to the customer’s process via a fine filtration stage, or it is fed to the separately available Mix & Transfer module. Due to the modular design, the equipment may easily be implemented in an existing sub-fab.

Re-use & Quality Improvement

The patented recycling plant offers the opportunity to recover and re-use the utilised materials. Resources are thus completely exploited. The quality standards of the chemical raw materials are maintained by the recycling process.

Resource-efficient by Recycling Quota

The re-use of chemical raw materials and process water (permeate) results in significant savings in the production process. Thanks to a recycling rate of up to 85%, only 15% of new raw materials need to be added. This significantly reduces the need for raw materials.

Protection of Water Resources

This recycling plant offers an important contribution to protecting the environment. Harmful nanoparticles are filtered out of the wastewater and this provides a better water quality. The reduced consumption of non-renewable raw materials saves important and valuable resources.

Cost Savings due to Backflushing Processes

The patented and self-cleaning backwashing process of the ultrafiltration modules leads to a significantly longer lifetime of the very cost-intensive filter elements. This pushes the cost efficiency of the entire system.

| Storage tank | 2500 L |

| Permeate tank | 1000 L |

| Return tank | 1800 L |

| Dimensions (L/W/H) | 3600/1650/2612mm |

| Weight | 1,8t (leer) 4,5t (maximal) |

Specifications and main features

- Recycling of used sludge, recycling rate > 80%.

- Recycling of used water, recycling rate > 80%.

- Liquid extraction > 85 l/min and > 3 bar

- Remote maintenance via TCP/IP

- Fully automatic system

- User-friendly touchscreen user interface

- Control system S7 PLC

- Visible/audible warnings and alerts

- Password protected operating levels

- High safety standards

- Real-time pre-warning for filter change

- CE certification

Materials

- PP (Polypropylene)

- PFA (Perfluoroalkoxy)

- PVC (Polyvinyl Chloride)

Operating system

- Movicon Scada/HMI

- MS Windows (Microsoft Windows)

Standard analytics

- Density

- Total percent solids

- pH value

- Conductivity

Optional quality control

- Viscosity

- LPC (Bulk counter)

- PSD (Particle Size Distribution)

- Zeta potential (electrokinetic potential)

- Metal analytics

- Silicate

Requirements

- Waste water free from organic solvents and oxidizing agents

- No copper or tungsten impurities

- Temperature: 15°C – 30°C / 59°F – 86°F

- pH value: 2 – 11

Mix & Transfer Module

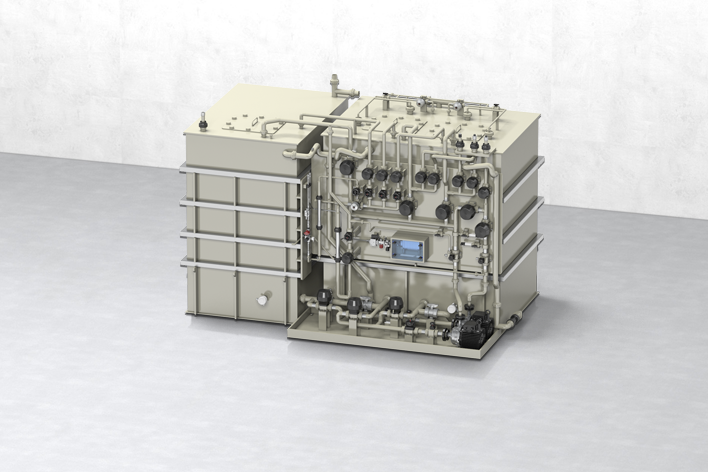

The Mix & Transfer module includes two mixing tanks and one transfer tank. The mixing tank module is used to mix the recycled slurry with the original slurry according to the specified recycling rate.

The storage tank is used to buffer the ready-mixed slurry. From the storage tank, the processed slurry is available for the process again via a transfer pump. The module is automated and equipped with modern monitoring technology. The overall control of the module is operated by the central recycling module.

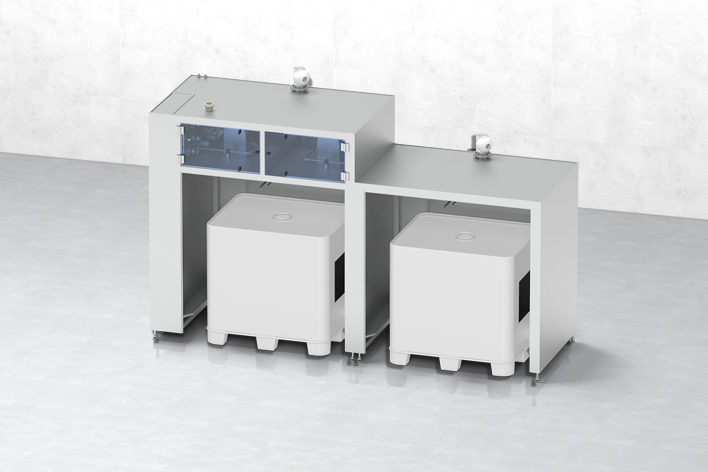

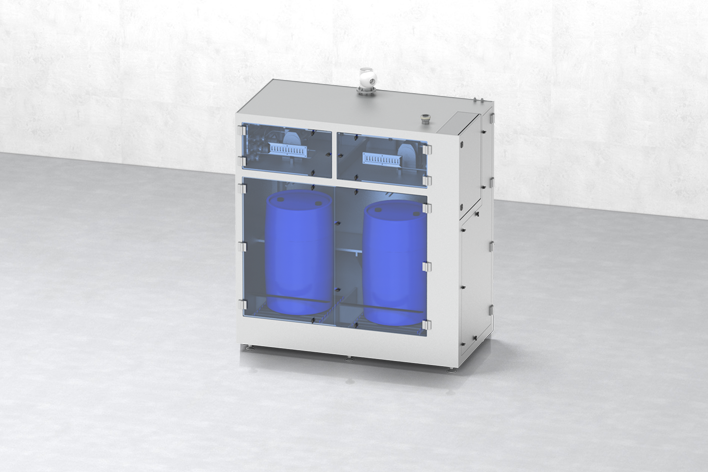

Fresh Slurry Supply System

The chemical supply module is used to supply the original slurry to the Mix & Transfer module and it is equipped with two slots for chemical containers. By accommodating two containers, it is possible to switch automatically from an empty container to a full container, thus ensuring an uninterrupted supply. In addition, a redundant pump module is integrated for an uninterruptible supply. The chemical supply module is automated and controlled by the central recycling module.

Chemical Supply Module

The chemical supply module is used to supply the original chemicals to the recycling module, and it is equipped with two bays for chemical containers. By accommodating two containers, it is possible to switch automatically from an empty container to a full container, thus ensuring an uninterrupted supply. In addition, a redundant pump module is integrated for an uninterruptible supply. The chemical supply module is automated and controlled by the central recycling module.

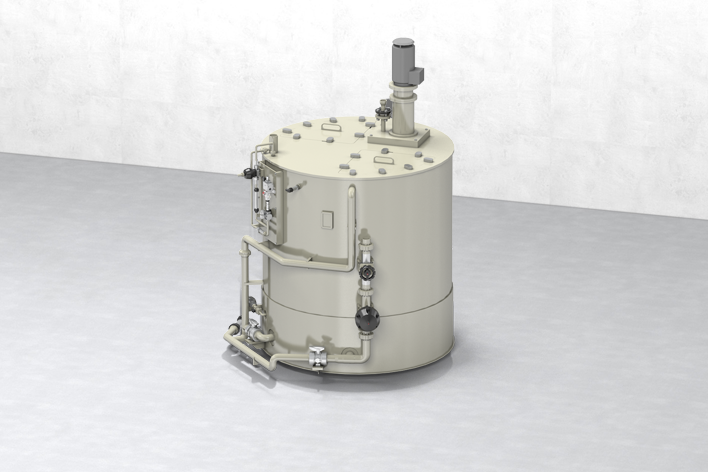

Wastewater Buffer Tank

The wastewater buffer tank serves as a buffer tank for the process of wastewater. The tank is equipped with a pump, pumping the wastewater to the recycling module, according to its requirement. The buffer tank is automated and controlled by the central recycling module.

Analysis Module

The analysis module serves as an additional monitoring of the Mix & Transfer module. Additional sensors and a sampling point are installed in the module, enabling the detailed online-monitoring of the mixture. The measured values are recorded and visualized in the overall control of the recycling module.

You may also find these topics interesting

Recycling system 1 UF

Discover the innovative Compact Recycling Module 1UF: Wastewater recycling & extended life-time of UF modules. Inform now!

Recycling System 8 UF

Discover the recycling module 8 UF HighQ: 9.0 m³/h throughput for first-class process solutions in the semiconductor industry! Learn more!

Recycling plants for the recovery of water

Discover the revolutionary recycling plant for the recovery of water: Environmentally friendly and efficient! Learn more now!